SureCrete RESIST Epoxy (2-Gallon)

SureCrete RESIST Epoxy Sand Overlay System with RESIST Armorstone Wear Aggregate and Eco-Stain accents

Stair tread close-up with RESIST Armorstone Wear Aggregate

Driveway with RESIST Goldmine Wear Aggregate

About

The SureCrete RESIST Epoxy Sand Overlay System

SureCrete’s RESIST is a 100% active, low modulus, two-component epoxy overlay system that when combined with a kiln-dried, properly sourced wear surface aggregate, produces a reliant overlay with benefits not found in traditional concrete overlays.

- Tenacious bond strength creating a durable, slip-resistant overlay system

- Superior resiliency and impact / wear resistance

- Bonds directly with the surface for exceptional chemical resistance and waterproofing

- Non-shrink and flexible enough to withstand slight movement and extreme temperature changes

- Cost effective with a 20 year history of high performance, repairs in the most extreme conditions

- Easy to use 1:1 mixing ratio

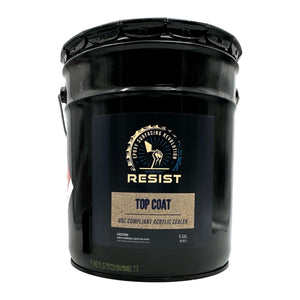

- Complete system that provides compatible products for crack repair, surface defects as well as a non-yellowing, color enhancing, protective top coat

See all of the products in the SureCrete RESIST Epoxy Sand Overlay System

Specs

| TECHNICAL DATA INFORMATION | |

|---|---|

| Coverage | Base Coat 150 sq ft per gallon base coat Second Coat 75 - 100 sq ft per gallon second coat with snd broadcast Coverage rates are provided as a guideline only. Many factors including surface texture, porosity and weather conditions will determine actual coverage rates. |

| Gel Time at 75° | 25-35 Minutes |

| Viscosity | 400-600 cps |

| A.I.M. Category | Concrete Protective Coating Maximum VOC 400 g/l |

| Applicable Standards |

|

| Testing Data | ASTM C882 – SLANT SHEAR BOND STRENGTH

|

Instructions

Preparation

- A proper inspection of the concrete is required to check for structural deficiencies, and any deteriorated areas should be promptly marked and removed.

- Repair delamination, potholes and cracks

- The entire surface should be shot blasted or ground to a CSP #2 to #3 or depth that ensures that all deteriorated and contaminated concrete (oil, dirt, rubber, paint carbonation, laitance, weak surface mortar, etc) is removed.

- Remove any remaining dust with compressed air, using a properly maintained and filtered compressor that will not spray oil or moisture onto the deck.

- If you pressure wash make sure concrete is fully dry. The overlay should be applied to the surface within 24 hours of cleaning.

- For applications exposed to heavy wear and/or in the case of concrete slabs that are soft or extremely porous, a base coat of RESIST Epoxy will be required. The base coat, applied at a rate of 200 sq’ per gallon, should be treated with a full broadcast of RESIST approved wear surface aggregate and allowed to cure prior to installing the main RESIST application.

- RESIST Sand Finish Overlay may be used at a range of temperatures, however the user should be aware that temperature plays a role in the pot life and cure times of this product. Higher temperatures will result in shorter pot life and cure times, while lower temperatures will result in longer pot life and cure times.

Mixing

- Mixing ratio for the two components is 1:1 by volume (not weight).

- Components “A” and “B” are supplied in separate containers and should be combined using a paddle mixer (powered by a low speed electric drill) or a proportioning pump for 3-5 minutes.

- RESIST SAND FINISH OVERLAY does not contain volatile solvents and solvents should not be added to this product.

- When using the Armorstone aggregate, you will simply Part A and Part B as described above.

- When using the Goldmine aggregate, you will need to add the Antique White 1 Quart Universal Tint Paste per every 2 Gallons of mixed material (1-Gallon Part A & 1-Gallon Part B.). Best practice is to introduce the 1 quart of colorant into the Part A (1 Gallon, mix thoroughly) and then introduce Part B into that colored Part A.

- When using the Silver Fox aggregate, you will need to add the Silver Gray 1 Quart Universal Tint Paste per every 2 Gallons of mixed material (1-Gallon Part A & 1-Gallon Part B.). Best practice is to introduce the 1 quart of colorant into the Part A (1 Gallon, mix thoroughly) and then introduce Part B into that colored Part A.

Application

This product should be used immediately upon mixing as this will increase its available working time.

- The mixed epoxy should be poured onto the surface and spread at the proper application rate using a notched squeegee (a notched squeegee will facilitate proper mil thickness).

- Back roll with a 3/8 to 1/2 inch roller to ensure all lines are evened out.

- Immediately follow this with a broadcast of sands over the epoxy at a rate sufficient to completely cover the epoxy. If need be, recoat with sand to make sure epoxy is covered.

Pro Tips

- Stage work stations.

- Load sands in easy scoopable trays for broadcasting.

- Dispense contents from mixing bucket immediately to avoid the epoxy from setting rapidly in the bucket.