SureCrete MicroTek One Coat Microcement Overlay for Concrete | 40 lb

About

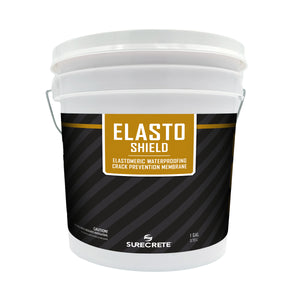

MicroTek One Coat is a professional-grade microcement overlay designed for interior and exterior walls, bathrooms, fireplace surrounds, and floors. Unlike standard overlays limited to concrete, MicroTek can be applied directly over drywall or cement board when primed with SureCrete ElastoShield, making it one of the most versatile wall finishing products available.

Available in Gray or White, the White base should be used if adding pigment with SC Color Packs or XS Color Packs for custom decorative finishes. Each 40 lb. bag provides 200–300 sq. ft. of coverage per coat, depending on application technique and surface conditions.

Whether updating a bathroom, refinishing drywall, transforming interior or exterior walls, or creating a sleek fireplace surround, MicroTek One Coat delivers a durable and elegant microcement finish for both DIY and professional projects.

Calculator

How many square feet is your project?

*Note: Coverage rate varies based on substrate and application techniques

Specs

Coverage: Approx 200-300 square feet per coat (Varies based on substrate and application)

VOC Content: 0 g/L

Shelf Life: 1 year in original unopened bag

Mixing Ratio: 5-6 quarts water per 40 lb bag

Base Color: White

Density: 126.1 lbs/cubic foot

Compressive Strength: ASTM C-109: 4,278 PSI @ 28 days

Flexural Strength: ASTM C-348: 995 PSI @ 28 days

Tensile Strength: ASTM C-190: 440 PSI @ 28 days

Abrasion Resistance: ASTM D-4060: 28 days %loss – 500 cycles – less than 0.50%

Mosaic Shear: ANSI A 118.4: 280 PSI @ 28 days

Instructions

Surface Preparation

The principles for surface preparation for Microtek are aligned with other cement-based overlays; the substrate must be:

- Clean: The surface must be free of dust, dirt, oil, grease, paints, glues, sealers, curing agents, efflorescence, chemical contaminants, rust, algae, mildew and other foreign matter that may serve as a bond breaker.

- Cured: Any concrete must be sufficiently cured to have sufficient hydration, approximately 7 - 14 days depending on temperatures and humidity

- Sound: No system should be placed upon a substrate that is flaking, spalling, or has hibernating spalling.

- Profile - Floors: Proper profile should follow the standard established by the International Concrete Repair Institute (ICRI) Technical Guideline no. 03732 for Concrete Surface Profile (CSP). The established profile is categorized as CSP-1 through CSP-3. The most common means to properly profile many concrete slabs is through the use of SCR (see SCR TDS). Some concrete slabs that are hard troweled or that are not sound may require more aggressive profiling achieved through diamond grinding or shot blasting. Customarily profiling is not required for application over another cement- based overlay.

- Profile - Walls: Customarily profiling is not required for vertical application on a substrate. On concrete the use of SCR is recommended. Most painted surfaces require de-glossing or sanding. Drywall surfaces require finishing and priming prior to application.

Temperature/Dry/Cure

- Air and substrate surface temperatures shall remain between 50°F (10°C) and 90°F (32°C) during and within 48 hours of placement.

- Cooler conditions will take significantly longer to cure.

- This product (depending on weather conditions) should achieve initial set within 6 – 8 hours. Like concrete, full cure is reached at 28 days.

- Sealer selection for a finished Microtek project will require different cure times:

- SureSeal products may apply as soon as overnight. See specific sealer TDS.

- Dura-Kote products may require longer cure times, perhaps 24 hours or more. See specific sealer TDS.

Application

Patching

Upon surface preparation, some areas may require patching prior to application of Microtek. Flash Patch or Deep Level is an excellent choice as a patching product to restore concrete to a sound state. Refer to Flash Patch or Deep Level TDS.

Crack Treatment / Construction Joints

Cracks may require treatment: Refer to Deep Level and TK 9030 Epoxy Crack Treatment TDS to evaluate crack as static or structural to set expectation of treatment.

Never bridge Microtek across any joint in concrete. Construction Joints in concrete have sufficient movement to “telegraph” through Microtek applications. Large expansive slabs should have planned appropriate flexible caulks to allow for this movement.

Mixing and Handling

- Add water, approximately 5 qt. (4.7 liter) to a 5 gal. (18.9 liter)

- Add 1 - Color Pack if desired. Caution: Color Packs may streak, as color particulate is larger than aggregate of mix.See Color Pack TDS.

- Mix with a handheld concrete mixer, such as a Collomix Xo-55 Dual Shaft Mixer. Color Packs require comprehensive mixing in water prior to introduction of Microtek.

- Slowly introduce Microtek into the pail with mixer running.

- Scrape side of pail with a margin trowel to ensure all dry product is incorporated into the wet mix.

- Continue to mix for a minimum of 1 minute after all ingredients are combined to achieve a lump-free consistency.

- Additional water may be added up to 6 quarts (5.7 liters) total for 40 pound (18.1 kg) bag.

First Coat

Microtek may be applied as a single coat system.

Floor

- The surface should be saturated, surface dry (SSD or damp, no puddles).

- Pour a generous ribbon of Microtek and tightly trowel or squeegee product over entire area.

Wall – Utilize a hawk and trowel and tightly coat surface with trowel

(Optional) Stencils and grout tape patterns

- Stencils and tape patterns may be placed after scraping and sweeping of first coat, and prior to application of finish coat.

- Stencils and tape patterns may be removed as soon as product dries sufficiently to bear the foot traffic of the applicator, prior to sealing.

Finish Coat

Floor

- Depending upon substrate’s condition and desired level of flatness or smoothness, a second or finish coat may be required.

- The first coat must set sufficiently to bear the foot traffic of the applicator, usually overnight (depending upon weather).

- The first coat may be scraped or sanded smooth and the surface swept or vacuumed.

- The finish coat applies as the first coat described above. Alterations of trowel techniques will yield numerous pleasing finish coats.

Wall

- Depending upon substrate’s condition and desired level of flatness or smoothness, a second or finish coat may be required.

- The first coat must set sufficiently to support finish coat, approximately 2-6 hours.

- The finish coat applies as the first coat described above. Alterations of trowel techniques will yield numerous pleasing finish coats.

Secondary Coloring

Depending upon the application selected, secondary coloring will provide aesthetic appeal to a project.

- Eco-Stain - 30 water base stain colors. Refer to Eco-Stain TDS.

(Note: Before secondary coloring, the finish coat must dry sufficiently to bear the foot traffic of the applicator [if on floor], usually overnight [depending upon weather]. Scrape the surface of finish coat with a floor scraper and remove any loose material.)

Sealing To complete a Microtek project sealing is required. Excellent sealer choices for economical floor projects include:

- HS 200LV - 20% solids, 400 g/L solvent

- HS 300LV - 30% solids, 400 g/L solvent

- Super WB – 30% solids water based

Refer to the appropriate TDS for details.

Other sealer choices for floors with enhanced durability properties include:

- DK 400 High Gloss

- DK 400WB Gloss & Satin

- DK 120 Polyaspartic High Gloss

- XS-327 Matte & Semi-Gloss

Refer to the appropriate TDS for details.

For Sealing Walls, Products to Consider:

- Super WB Low Luster & High Gloss

- XS-327 Matte & Semi-Gloss

Refer to the appropriate TDS for details.

(Note: if secondary coloring is not utilized before sealing, scrape the surface of finish coat with a scraper and remove any loose material.)

Slip Resistance

Two recognized US agencies have issued directives on minimum coefficient of friction, OSHA (Occupational Safety and Health Administration) and Department of Justice through the ADA (Americans with Disabilities Act). ADA is the more stringent of the two. ADA directs that accessible walkways have a minimum coefficient of friction of 0.6. Ramps have been directed to be 0.8. The applicator assumes the responsibility to meet these standards. Especially exterior surfaces or surfaces that may become wet, oily, or greasy require attention. Refer SureGrip (Additive) TDS and its accompanying coefficient of friction table.

Clean Up

Before Microtek dries; spills and tools can be cleaned up with water.

Disposal

Contact your local government household hazardous waste coordinator for information on disposal of unused product.

See More